Rubber Lining Alternatives

We provide a range of sprayable rubber lining alternatives that are fast to apply, seamless and easily repairable.

We work with various coatings and linings manufacturers that offer ultra-durable wear linings and chemical protection coatings systems that offer many benefits to traditional rubber lining. Rubber lining provides a high level of protection to assets however is slow to apply and has disadvantages including joints between sheets (which are common points of failure). When a rubber joint fails, the harmful substances can make their way behind the lining, causing rapid damage to the substrate. The benefit of spray-applied coatings and linings is they are seamless and have no weak point for failure. Additionally, spray-applied coatings are faster to apply than rubber and assets can be returned to service rapidly, often within hours.

Polyurea coatings

Polyurea coatings are an excellent high build and low cost solution for assets requiring robust protection.

The rapid set nature of polyurea allows other SIMOPs to continue and applicators can walk over freshly coated components within minutes. The equipment can then be returned to service within hours.

With the ability to apply a system up to 20x thicker than traditional coatings, Polyurea ensures that the underlying assets are well protected from harmful operating conditions. They can be applied at high build thicknesses ranging from 1-50mm. This high build layer offers a superior barrier and often for the same total cost as traditional thin epoxy and polyurethane coatings. Polyurea coatings also act as tough wear linings against debris and offer a viable alternative to costly rubber lining systems.

Polyurea repairs are easier to both apply and repair than alternatives such as rubber linings. Polyurea coatings can be quickly repaired during maintenance and shutdown periods - the damaged or worn areas simply need to be cleaned and prepared, and a fresh layer of coating can be applied over the area. Additionally, polyurea can be applied in a dual colour system so that when the second colour becomes visible, maintenance crews are visually notified that the coating is at about 50% remaining thickness.

MetaLine® Series 700

Rubber-like coatings that absorb destructive impact energy through permanently elastic properties.

MetaLine Series 700 is a sprayable elastomeric product that combines the performance of vulcanised rubber linings and the simplicity of spray coatings. Unlike rubber linings, Metaline has no seams that could fail and does not suffer from restricted and costly repairability. The strength of MetaLine Series 700 lies in its erosion and cavitation resistance, which is comparable to high alloy steels and armours.

MetaLine 700 series is spray applied using 1kg cartridge kits that can be equipped with straight or 90 degree nozzles allowing for application to small and complex shapes.

We have over a decade of experience in applying MetaLine to a wide variety of assets including pumps, rollers, rake arms, tanks, shaker screens, slurry pipes, agitators and more.

Application Examples

Tanks

Thickener tank rubber lining removal and relining.

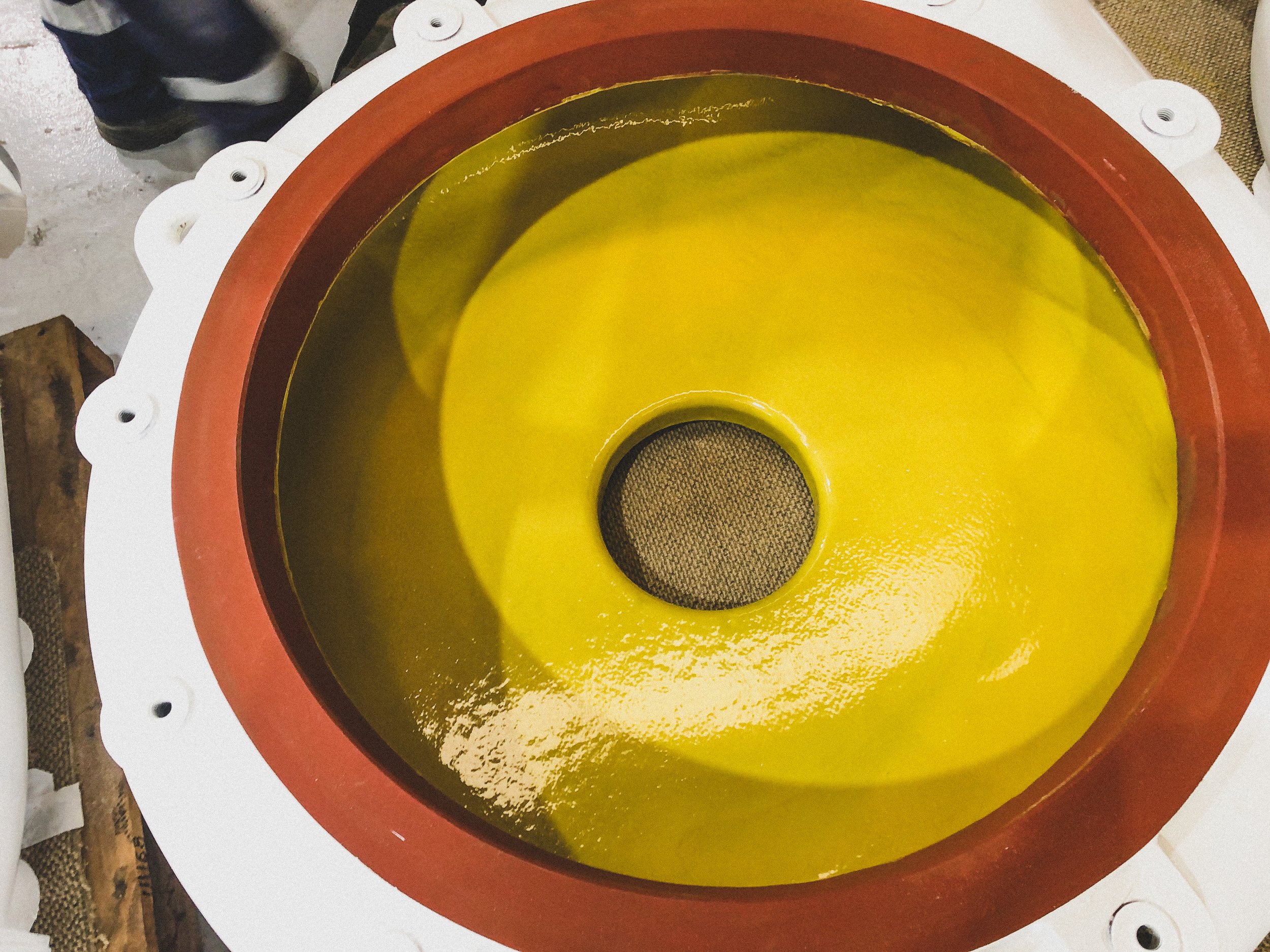

Pumps

Remediation of slurry pump lining using MetaLine 785.

Agitators

Seamless MetaLine 785 coating to a mine site tank agitator.