Dry Ice (CO2) Cleaning

Dry ice blasting is a non-abrasive, non-conductive, non-flammable, and non-toxic method of safely cleaning surfaces and removing unwanted coatings such as paint or rust.

Using our dry ice capability, we can effectively clean surfaces and recesses in a fraction of the time of traditional cleaning methods, which often include the risk of component and substrate damage. Dry ice blasting with frozen carbon dioxide leaves no liquid waste as the ice turns immediately from a solid to gas.

Food Production

No secondary contaminants, solvents or grit media are produced during dry ice cleaning.

Dry ice blasting is a non-abrasive, non-conductive, non-flammable, and non-toxic method of safely cleaning surfaces. This makes it a perfect cleaning method for food production facilities.

Dry ice cleaning services also reduce labour and other operational costs. The practice is faster and more productive than manual cleaning while also reaching into areas that manual cleaning cannot.

Our team can rapidly clean your food and beverage managing facilities, including storage tanks, ovens, conveyors, packaging lines and all manner of robotic production line machinery.

Plant and Equipment

Decontaminate your plant equipment whilst it is still in service.

Dry ice cleaning can remove grease and dirt buildup from lathes, compressors, generators, CNC machines, brake presses and more. Due to the nature of dry ice cleaning, there is no need for the isolation of equipment. We can conduct rapid turnaround cleaning of your key plant to keep your operation running smoothly.

Our capability can be rapidly deployed to your site and restore your plant and equipment to near new cleanliness with little to no downtime.

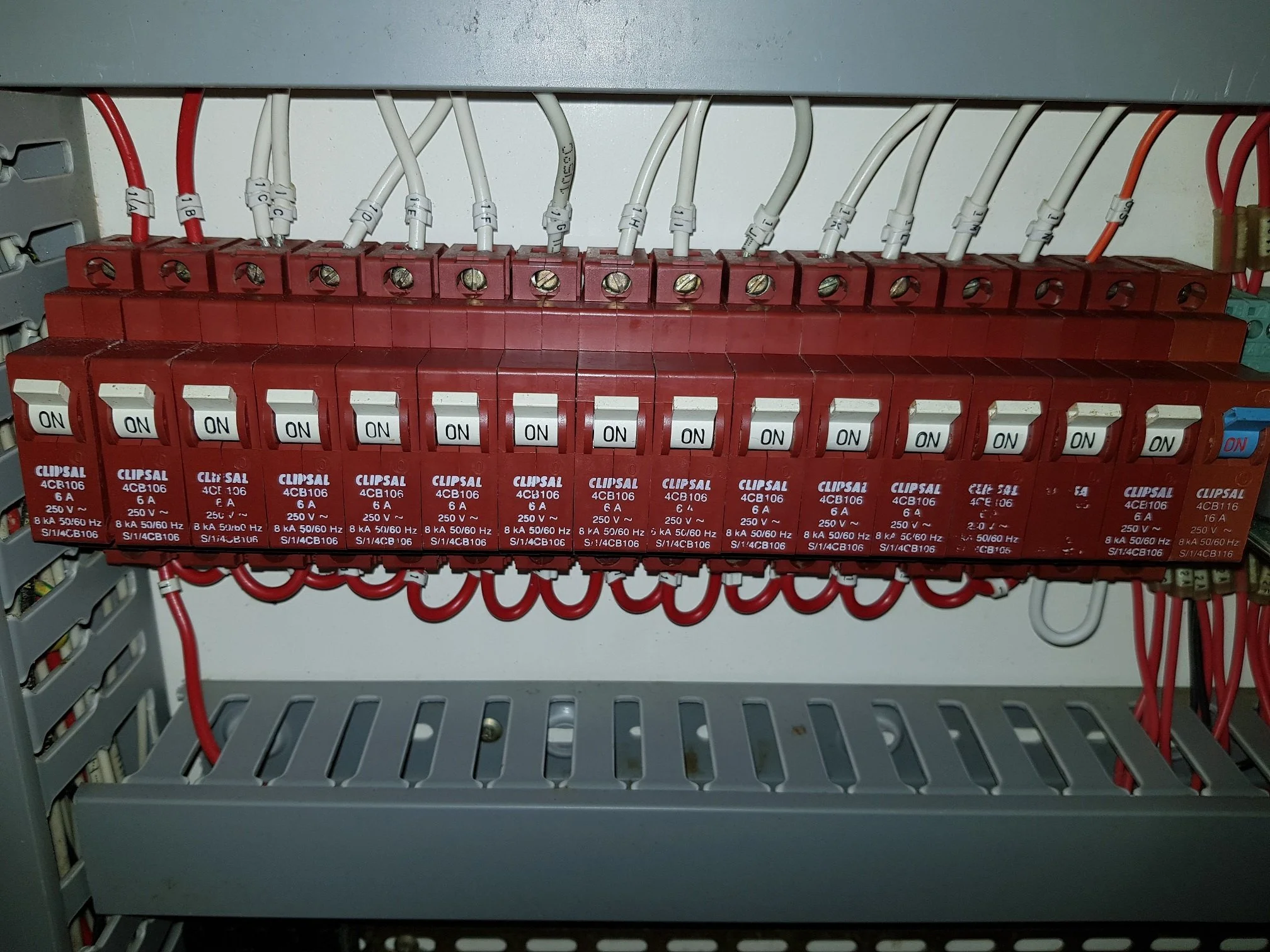

Live Electrical Componentry

Dry ice cleaning is a dry and inert process that does not interfere with electrical equipment.

In an industrial setting, dry ice allows for cleaning in place without disruption or disassembly of equipment, and there is no risk of electrical failure or damage.

Our teams have experience in cleaning a wide range of low and high-voltage electrical assets, including transformers, radiators, bushings, structural steel and switchboards.

The lack of water or moisture also allows for machinery to be started up again immediately after cleaning (or cleaned while in service), reducing downtime and increasing operational efficiency.