Belzona Coatings & Repair Composites

Belzona’s innovative protective coatings and repair composites preserve assets and extend their service life, protecting them from challenging environments and operating conditions. Manufactured with 100% solids and free of solvents, Belzona is your environment-friendly choice.

IND has been an approved applicator and distributor of Belzona’s full range of products for over a decade. We have the depth of experience to apply Belzona’s innovative solutions on the most challenging projects and applications.

Belzona’s innovative solutions include:

Metal repair composites: epoxy composites containing metal and carbide fillers including Belzona 1111, 1311 and 1511 that can be used to rebuild corrosion pitting and plate bond steel plates to damaged assets with no hot works.

Specialist protective coatings: Belzona 1391T (trowel-able), 1391S (sprayable) and Belzona 5811 (immersion grade).

Leak repair solutions: surface-tolerant epoxy composites engineered specifically for tough applications including to wet, contaminated and immersed surfaces where traditional repairs (such as welding are not feasible. e.g Belzona 1212.

Belzona SuperWrap II: offers a new generation repair solution for restoring the strength of holed, weakened and corroded pipe and tank walls. It is comprised of a fluid-grade resin system, a bespoke hybrid reinforcement sheet, based on fibre glass and carbon fibre, as well as a release film to compact and consolidate the application. Belzona SuperWrap II Can be designed and applied in accordance with ISO24817 and ASME PCC-2 standards and applied by our trained and validated personnel.

Concrete repair composites: epoxy repair composite designed for repair, resurfacing and protection of concrete and stone e.g Belzona 4111 (Magma-Quartz).

Flange encapsulating membranes: hybrid polymer coatings for the encapsulation of any shape, size or configuration of flanged joint or other equipment. Designed to exclude moisture and prevent crevice, galvanic and atmospheric corrosion e.g Belzona 3412.

Our in-house AMPP (previously NACE) certified coating inspectors oversee our strict quality requirements using our ISO 9001-certified quality management systems. With an extensive range of testing equipment and qualified inspectors, we excel in projects where strict adherence to specifications is imperative and can assist in pre-execution activities including condition assessments, specification development and project management.

Application Examples

Intercooler relining

Relining of Nickel mine intercoolers using Belzona 1523.

Leaking storage tank repair

Plate bonding using Belzona 1111 to seal leaking water storage vessel.

Pump coatings

Pump internal lined with Belzona 1341.

Vessel plate bonding

Plate bonding over through wall defects on a digester tank.

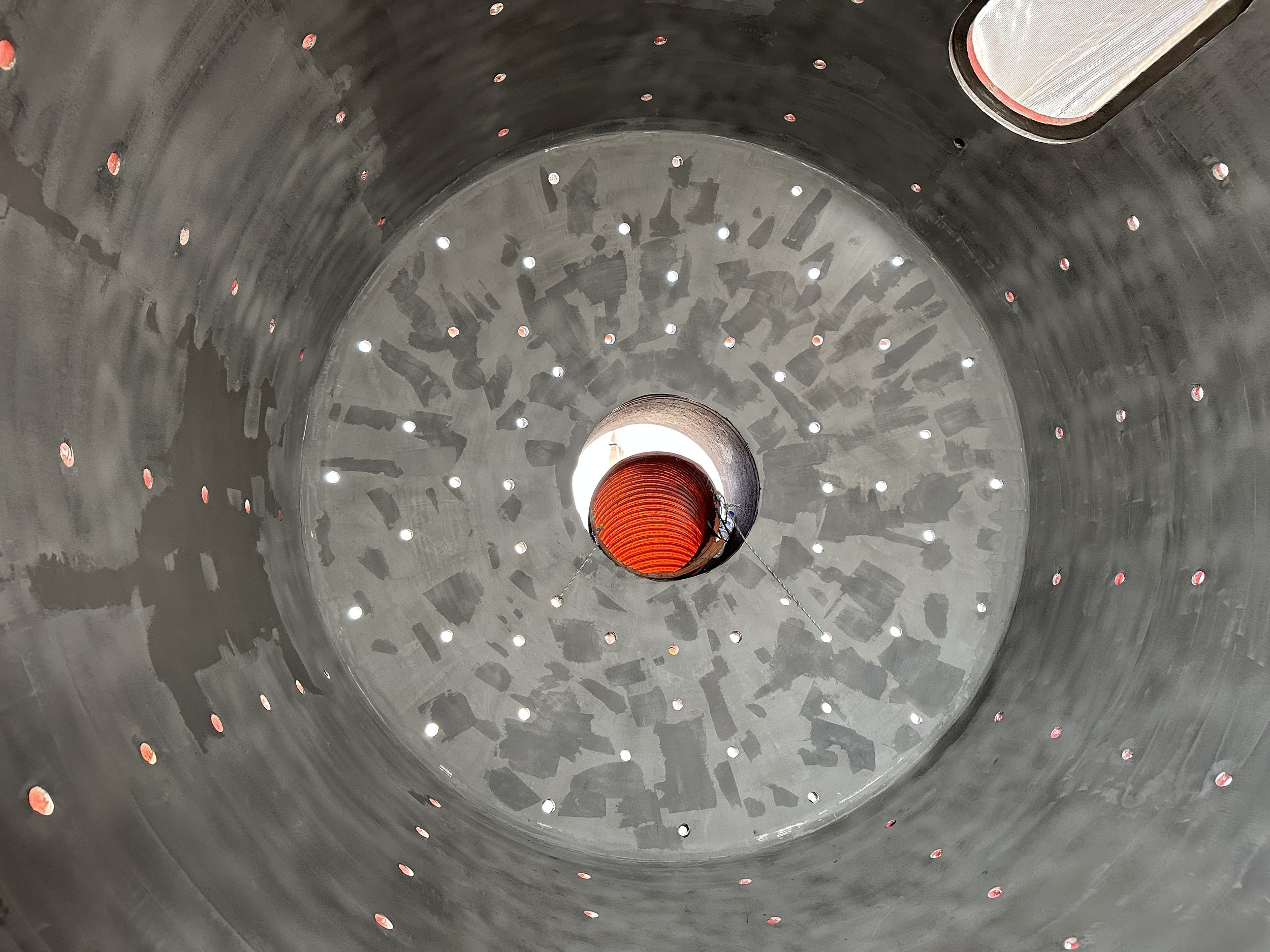

Ball mill resurfacing

Resurfacing of heavily pitted ball mill using Belzona 1812, 1111 and 1311.

Tank lining

Thickener tank relining with Belzona 1391S

Heat exchangers coatings

Refurbishment of heat exchanger ends using Belzona 1321.

Transformer leak repairs

Leak repairs on transformer gaskets using Belzona 1212.

Flange face reforming

Refacing of pitted flange faces using Belzona 1111.